Introduction

PRECISE® N series needle valve is improved and perfected continuously on the basis of importing and digesting home and abroad advanced needle valve. It has the following features: advanced structure, reliable performance, simplify operation, convenient maintenance and etc. It's widely used in these industries such as hydro power, irrigation and drainage, water works, water diversion and so on.

1.With 90°layout (N10 type)、 120°layout (N20 type)or135°layout (N25 type)

2.With manual operation, electrical/manual operation, hydraulic operation

3.With clearly mechanical valve opening indicator

4.With full open and full close position output signal (Please clarify particularly with manual operation)

5.The regulating type needle valve with DC4~20mA (Default) or 0~5V valve opening real time output signal

Product Performance

☆High resist cavitations corrosion capability

☆Minimum vibration and noise

☆Sealing reliable

☆The sealing seat's material is the stainless steel for a special use in hydropower

☆Convenient installation and maintenance

Typical Application

☆ In-line cutoff and regulate or control the pressure or flow of the pipeline

☆ Terminal regulation free discharge to atmosphere

☆ Terminal regulation submerged discharge

☆ Penstock valve by-pass system

☆ By-pass filling valve of the inlet valve of the hydraulic turbine

Typical Structure

| No. | Component | Material |

| 1 | Body | Carbon steel or stainless steel |

| 2 | Sealing seat | Special stainless steel |

| 3 | Plug | stainless steel |

| 4 | Sealing | NBR or EPDM |

| 5 | Gland | Copper alloy |

| 6 | Cylinder | Carbon steel |

| 7 | Bracket | Carbon steel |

| 8 | Bush | Carbon steel |

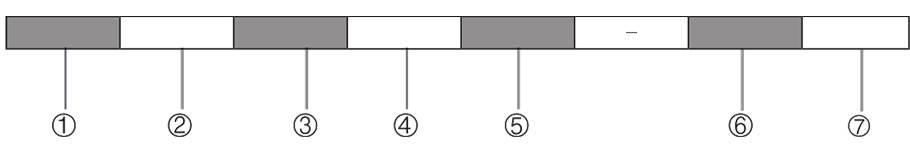

Model Designation

① Valve Type Code: N10—the included angle is 90°inlet flange face with outlet flange face;N20—the included angle is 120°inlet flange face with outlet flange face;

② Driving mode code: M—Manual driving mode;E—Electric/manual driving mode;H—Hydraulic driving

③ Nominal diameter of valve: unit, mm

④ Sealing code: H-stainless steel

⑤ Functional code:1-switch; 2-adjustment

⑥ Nominal pressure: unit, bar (10×MPa)

⑦ Characteristic code: A1~A9;B1~B9......

Type illustration:

Nominal diameter 200mm, nominal pressure 10MPa, stainless steel sealing hydraulic driving,type switch, needle valve with the included angle is 90° inlet flange face with outlet flange face,type:N10H200H1-100A1.

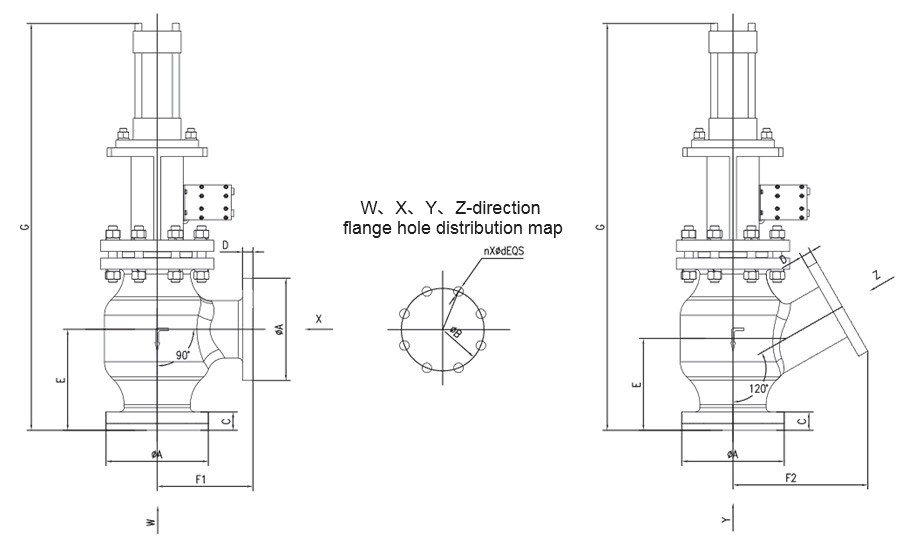

Overall Dimension

| DN | PN | A | B | C | D | E | n-d | F1 | F2 | G |

| 80 | 1.0 | 200 | 160 | 38 | 20 | 208 | 8-18 | 192 | 300 | 970 |

| 1.6 | 200 | 160 | 38 | 20 | 208 | 8-18 | 192 | 300 | 970 | |

| 2.5 | 200 | 160 | 42 | 24 | 212 | 8-18 | 196 | 304 | 975 | |

| 4.0 | 200 | 160 | 42 | 24 | 212 | 8-18 | 196 | 304 | 975 | |

| 6.3 | 215 | 170 | 46 | 28 | 216 | 8-22 | 200 | 310 | 985 | |

| 10.0 | 230 | 180 | 50 | 32 | 220 | 8-26 | 204 | 315 | 995 | |

| 100 | 1.0 | 220 | 180 | 40 | 22 | 230 | 8-18 | 218 | 370 | 1000 |

| 1.6 | 220 | 180 | 40 | 22 | 230 | 8-18 | 218 | 370 | 1000 | |

| 2.5 | 235 | 190 | 42 | 24 | 232 | 8-22 | 220 | 372 | 1002 | |

| 4.0 | 235 | 190 | 42 | 24 | 232 | 8-22 | 220 | 372 | 1002 | |

| 6.3 | 250 | 200 | 48 | 30 | 238 | 8-26 | 226 | 378 | 1110 | |

| 10.0 | 265 | 210 | 54 | 36 | 244 | 8-30 | 232 | 385 | 1120 | |

| 150 | 1.0 | 285 | 240 | 42 | 24 | 246 | 8-22 | 256 | 410 | 1250 |

| 1.6 | 285 | 240 | 42 | 24 | 246 | 8-22 | 256 | 410 | 1250 | |

| 2.5 | 300 | 250 | 46 | 28 | 250 | 8-26 | 260 | 414 | 1254 | |

| 4.0 | 300 | 250 | 46 | 28 | 250 | 8-26 | 260 | 414 | 1285 | |

| 6.3 | 345 | 280 | 54 | 36 | 258 | 8-33 | 268 | 422 | 1315 | |

| 10.0 | 355 | 290 | 62 | 32 | 266 | 12-33 | 276 | 430 | 1350 | |

| 200 | 1.0 | 340 | 295 | 42 | 38 | 287 | 8-22 | 294 | 480 | 1450 |

| 1.6 | 340 | 295 | 42 | 26 | 287 | 12-22 | 294 | 480 | 1450 | |

| 2.5 | 360 | 310 | 48 | 28 | 295 | 12-26 | 294 | 486 | 1485 | |

| 4.0 | 375 | 320 | 52 | 34 | 300 | 12-30 | 305 | 495 | 1493 | |

| 10 | 430 | 360 | 86 | 52 | 230 | 12-36 | 320 | 415 | 1550 | |

| 250 | 1.0 | 395 | 350 | 44 | 26 | 342 | 12-22 | 320 | 520 | 1650 |

| 1.6 | 405 | 355 | 44 | 26 | 342 | 12-26 | 320 | 520 | 1650 | |

| 2.5 | 425 | 370 | 50 | 32 | 348 | 12-30 | 326 | 526 | 1680 | |

| 4.0 | 450 | 385 | 56 | 38 | 354 | 12-33 | 342 | 542 | 1720 | |

| 300 | 1.0 | 445 | 400 | 44 | 26 | 392 | 12-22 | 352 | 580 | 1900 |

| 1.6 | 460 | 410 | 46 | 28 | 394 | 12-26 | 354 | 582 | 1902 | |

| 2.5 | 485 | 430 | 52 | 34 | 400 | 16-30 | 360 | 590 | 1910 | |

| 4.0 | 515 | 450 | 60 | 42 | 410 | 16-33 | 380 | 610 | 1930 | |

| 400 | 1.0 | 565 | 515 | 51 | 26 | 540 | 12-26 | 500 | 700 | 2100 |

| 1.6 | 580 | 525 | 57 | 32 | 546 | 16-30 | 506 | 706 | 2190 | |

| 2.5 | 620 | 550 | 65 | 40 | 554 | 16-36 | 514 | 714 | 2250 | |

| 4.0 | 660 | 585 | 75 | 50 | 564 | 16-39 | 524 | 724 | 2300 | |

| 500 | 1.0 | 670 | 620 | 58 | 28 | 650 | 20-26 | 610 | 820 | 2500 |

| 1.6 | 715 | 650 | 66 | 36 | 658 | 20-33 | 618 | 828 | 2580 | |

| 2.5 | 730 | 660 | 78 | 48 | 670 | 20-36 | 630 | 836 | 2630 | |

| 4.0 | 755 | 670 | 87 | 57 | 679 | 20-42 | 640 | 850 | 2700 |

Note: 1.The dimension sheet is as result of reference and different with various function.

2.Others of needle valve can be customized according to customer requirements

Prev:No Information!

Next:No Information!