Product Introduction

NNominal diameter: 200 ~ 2000 mm

Nominal pressure: 0.6 ~ 6.4 MPa

Flow capacity: 0 ~ 86400 ㎡/ h

Technical characteristics:

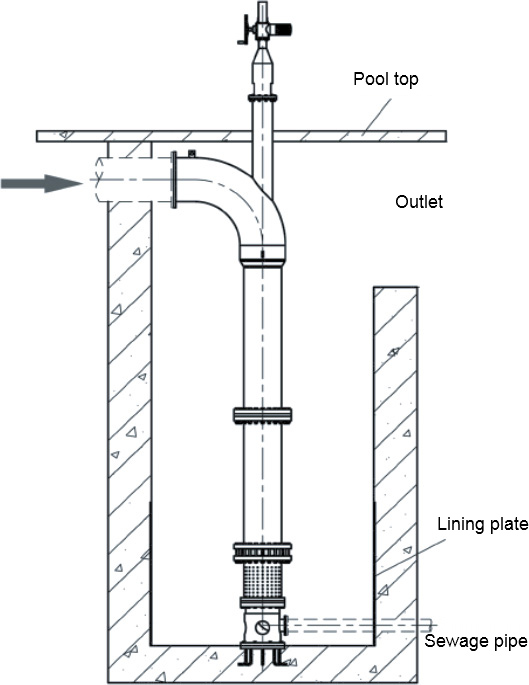

1.Submerged layout

2.Excellent anti-cavitation performance

3.Large decompression ratio of 20:1

4.The linear adjustment

5.Flow adjustment and pressure adjustment

6.High-precision adjustment valves

Driving mode: manual, electrical, hydraulic

Typical Application

Pressure of pipeline.

Accurate adjustment and control of flow.

Discharge of the dam.Ecological discharge control of bypass unit

Typical Structure

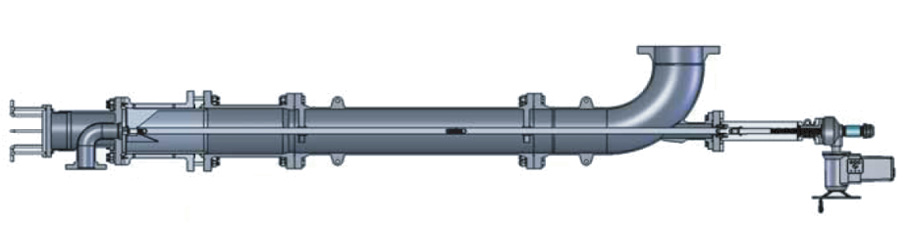

B11 series submerged multijet sleeve valve is mainly made up of inlet bent pipe, connecting pipe,sleeve, gate, actuator,transmission mechanism, sealing seat, sealing ring etc.

| Item | Name | Material |

| 1 | Inlet bent pipe | Carbon |

| 2 | Sealing seat | 304ss or 316ss+hard-alloy |

| 3 | Sleeve | 304ss or 316ss |

| 4 | Sealing ring | NBR or EPDM |

| 5 | Gate | 304 or 316 |

| 6 | Shaft | 304ss or 316ss |

| 7 | Connecting pipe | Carbon |

Principle

PRECISE® B11 series submerged multi-jet sleeve valve's flow control and energy consumption are achieved by switching the amount of jet of the sleeve. The sleeve jets are specially designed for each specific engineering. The sleeve valve has excellent anti-cavitation performance, through the unique anti-cavitation structure, so that the occurrence of cavitation valve could be away from the wall metal surface area, avoiding cavitation damage to the valve and reducing valve vibration and noise during run-time.

In practical operation of each project, the PRECISE ® B11 series of submerged multijet valve sleeve can provide optimal flow control or pressure control.

Hydraulic Parameter Table

| DN | Qmax | Cv | |||

| mm | in | m³/s | cfs | (m³/s)/√m | cfs/√psi |

| 200 | 8 | 0.30 | 10.47 | 0.09 | 2.74 |

| 250 | 10 | 0.46 | 16.35 | 0.14 | 4.28 |

| 300 | 12 | 0.67 | 23.55 | 0.21 | 6.20 |

| 350 | 14 | 0.91 | 32.05 | 0.28 | 8.40 |

| 400 | 16 | 1.19 | 41.87 | 0.37 | 11.00 |

| 450 | 18 | 1.50 | 52.99 | 0.47 | 13.90 |

| 500 | 20 | 1.85 | 65.42 | 0.58 | 17.10 |

| 600 | 24 | 2.67 | 94.20 | 0.83 | 24.70 |

| 750 | 30 | 4.17 | 147.19 | 1.30 | 38.50 |

| 900 | 36 | 6.00 | 211.95 | 1.87 | 55.50 |

| 1000 | 42 | 8.17 | 288.49 | 2.55 | 75.50 |

| 1200 | 48 | 10.67 | 376.80 | 3.33 | 98.70 |

| 1400 | 54 | 13.51 | 476.89 | 4.21 | 125.00 |

| 1500 | 60 | 16.67 | 588.75 | 5.21 | 154.00 |

| 1600 | 63 | 18.37 | 648.80 | 5.75 | 170.27 |

| 1700 | 67 | 20.734 | 732.50 | 6.50 | 192.48 |

| 1800 | 72 | 24.01 | 847.80 | 7.50 | 222.00 |

Overall Dimension

Please contact us for structure layout size of our products in detail.