Introduction

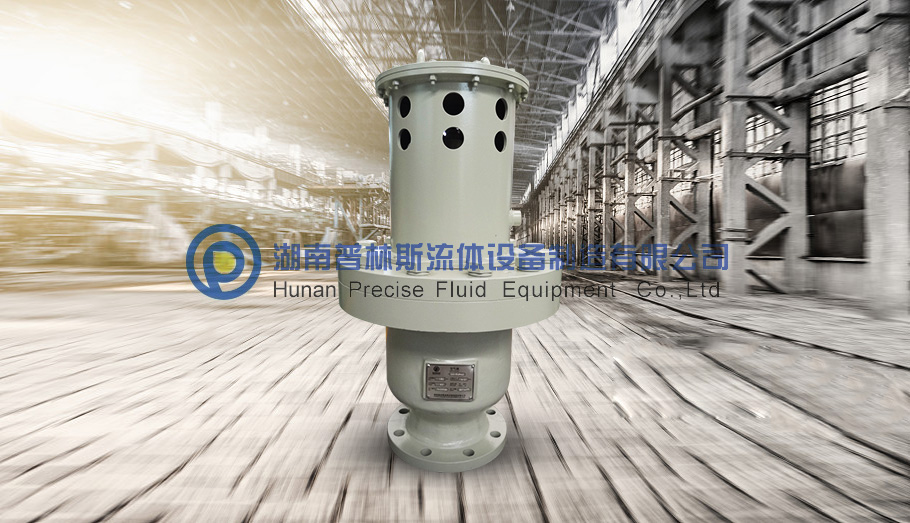

PRECISE ® A series air valves is a kind of Advanced piping control equipment which is improved and perfected continuously on the basis of importing and digesting domestic and foreign advanced sleeve valve, the main function is to destruct the pipe vacuum of the inflow and outflow of pipeline.It is made of type A10 inlet and exhaust and type A20 vacuum breaking valve.

A series air valve is mainly used for the following working conditions:

1.Natural air supply when units are in the operation in stability.

2.Volute exhausting when units are in the operation in Phase Modulation.

3.Automatically exhausting when units' main valves are in the concora crush.

4.Ventilating for Repairing and Maintaining unit's drainage sump of underground powerhouse.

5.Pipeline exhausting and automatically supply air in long-distance water pipelines.

6.Destructing the pipe vacuum.

7.Eliminating the water hammer of pipeline.

Main characteristics:

1.stable and reliable.

2.Huge air inflow and outflow.

3.Reliable sealing with compact structure.

4.Easy installation with small size.

5.Easy maintenance and long service life.

6.novel design and aesthetic appearance.

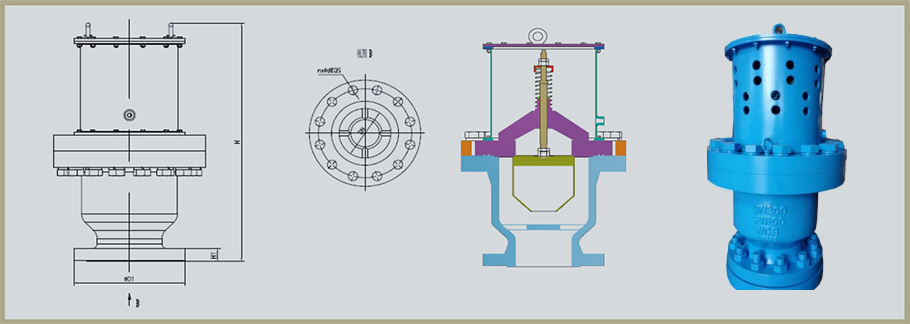

How it works

When the pipeline start waterfilling, the floats and the piston will fall to the lower limit due to Weight has overcome the elasticity of the spring, a large amount of air quickly released through the gap between the floats and valve seat. As the water level increases, the floats and the piston rise slowly until the upper limit position under the combined effect of buoyancy and spring force, at the same time the water with pressure goes into the tank through the air valve bypass tube, pushing the piston upward.Under the joint action of the media pressure and the elasticity and buoyancy,seal rings are forming a seal with the valve seat to stop air exhausting.

When the pipelines are empty flow or the negative pressure within pipelines, the floats and the piston move rapidly downward due to weight and negative pressure,sealing ring separate from the seat, quickly inhaling of ambient air to ensure pipeline safety.

When the normal long-distance pipeline conveyance, small amount of air automatically discharged through Additional bypass micro-air valve when small amount of air in the valve gathered to a certain extent.

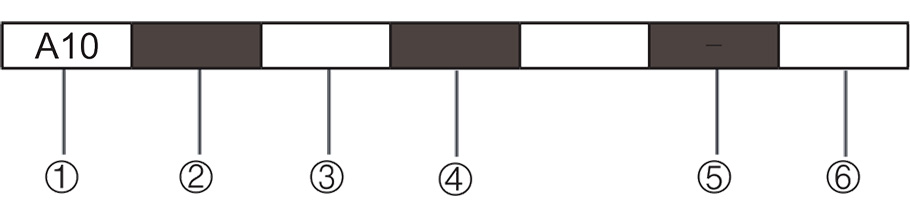

Model Designation

① Valve type code A10,Inlet and exhaust valve A20,vacuum breaking valve

② Driving mode code: N - No drive

③ Nominal diameter of valve: unit, mm

④ Sealing code:X-rubber;H-stainless steel

⑤ Nominal pressure: unit, bar (10×MPa)

⑥ Characteristic code: A1~A9;B1~B9......

Type illustration

Nominal diameter 200mm, nominal pressure 2.5MPa, rubber sealing , air valve;type:A10N200X-25A1.

Dimensions

| DN(mm) | PN(MPa) | D1 | D2 | n xφd | D3 | H | H1 | H2 |

| 80 | 1.0/1.6/2.5/4 | 200 | 160 | 8x18 | 290 | 700 | 24 | 200 |

| 6.3 | 215 | 170 | 8x22 | 330 | 830 | 28 | 230 | |

| 10.0 | 230 | 180 | 8x26 | 330 | 830 | 32 | 230 | |

| 100 | 1.0/1.6 | 220 | 180 | 8x18 | 270 | 720 | 22 | 200 |

| 2.5/4.0 | 235 | 190 | 8x22 | 270 | 720 | 24 | 200 | |

| 6.3 | 250 | 200 | 8x26 | 355 | 850 | 30 | 250 | |

| 10.0 | 265 | 210 | 8x30 | 355 | 850 | 36 | 250 | |

| 150 | 1.0/1.6 | 285 | 240 | 8x22 | 365 | 870 | 24 | 220 |

| 2.5/4.0 | 300 | 250 | 8x26 | 365 | 870 | 28 | 220 | |

| 6.3 | 345 | 280 | 8x33 | 450 | 1020 | 36 | 290 | |

| 10.0 | 355 | 290 | 12x33 | 450 | 1020 | 44 | 290 | |

| 200 | 1.0 | 340 | 295 | 8x22 | 395 | 1000 | 24 | 250 |

| 1.6 | 340 | 295 | 12x22 | 395 | 1000 | 24 | 250 | |

| 2.5 | 360 | 310 | 12x26 | 395 | 1000 | 30 | 250 | |

| 4.0 | 375 | 320 | 12x30 | 530 | 1180 | 34 | 330 | |

| 6.3 | 415 | 345 | 12x36 | 530 | 1180 | 42 | 330 | |

| 10.0 | 430 | 360 | 12x36 | 530 | 1180 | 52 | 330 |

Prev:No Information!

Next:No Information!